Shot Blasting

Gallery

Shot Blasting

Shot blasting process is an important method used to clean and roughen the surface of steel. This content will cover shot blasting unit, cleaning of steel, surface roughness, and shop primer application in detail.

HEATING AREA

A designated heating area must be capable of removing moisture and heating the steel to the appropriate temperature. To achieve proper drying conditions before paint application, the recommended steel temperature should be between 30 °C and 40 °C, depending on the type and thickness of the paint.

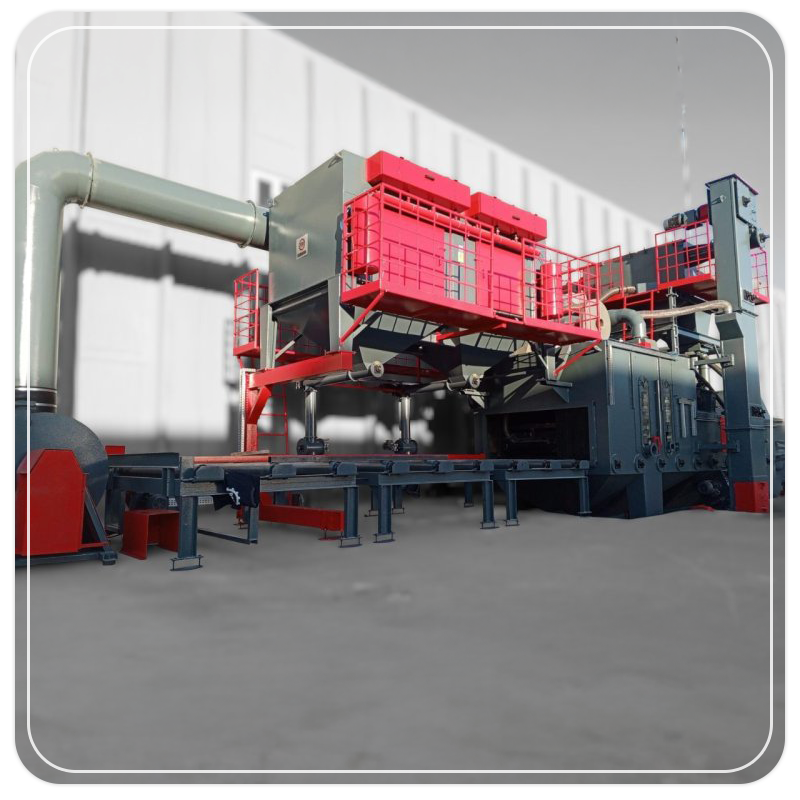

BLASTING UNIT

The blasting unit ensures the cleanliness of the steel (ISO 8501-1:1988 Sa 2 ½ - Very thorough blast cleaning) and provides the required surface roughness. In addition to the blasting system, there must also be a cleaning unit. This unit is essential for removing abrasive materials (grit, shot) and dust that have been sprayed onto the surface of the material.

STEEL CLEANLINESS

In order to achieve good corrosion protection after the application of shop primer, it is mandatory to perform surface preparation to Sa 2 ½ - Very thorough blast cleaning. In this process, the surface must be free of oil, grease, dirt, rust, paint residues, and other contaminants.

STEEL SURFACE ROUGHNESS

The blast cleaning unit will generate a rough surface profile on the steel. The degree of roughness depends on the type and size of the abrasive particles (grit, shot, etc.) and their impact speed on the steel surface. This roughness provides an ideal anchoring surface for the paint, significantly increasing paint adhesion.

When viewed under magnification, the surface profile consists of alternating valleys and peaks. For optimal paint application, the surface profile height (Ry – the amplitude between the peak and the valley) should be between 40-75 µm.

SHOPPRIMER APPLICATION

The painting cabin includes a system where spray nozzles move back and forth across the surface. These nozzles spray perpendicularly to the movement direction of the steel plates, applying paint using an overlapping method.

The painting booth must have effective ventilation to eliminate paint dust (dry spray) and evaporating solvents.

In addition to the booth, there should be a separate area for spray pumps and paint mixing. This enclosed area must comply with health and safety standards and be equipped with a good ventilation system to prevent fire hazards.

This area should include equipment that continuously mixes the paint in a tank to maintain its homogeneity.

DRYING AREA

The drying area must be sufficiently large to allow the paint to fully dry. To prevent air pollution from solvent emissions, this process should be carried out in a closed environment.