CNC Plasma Cutting Line

Gallery

CNC Plasma Cutting Line

Working principle and benefits of CNC Plasma cutting line

CNC Plasma Cutting Services

With its 3000x12000 mm CNC Plasma Cutting Machine, Baydemir is able to meet the plasma cutting needs of Aksaray, Niğde, Nevşehir, and surrounding provinces.

Equipped with experienced technical draftsmen, machine operators, and operator assistants, the plasma cutting unit sets the shortest possible delivery time based on customer demand, completes cutting processes with great precision, performs marking if required, and delivers the finished parts to the customer without defects or delays.

CNC Plasma Cutting Line

Using our Ajan CNC Machines:

- PLASMA CUTTING up to 1–50 mm,

- OXYGEN CUTTING up to 1–300 mm

CNC Ajan Plasma – Technical Specifications

- Steel construction body

- Double-sided rack and pinion system with AC servo motors for X-axis movement

- Rack and pinion drive with AC servo motor for Y-axis movement

- Plasma generator options:

- 100 Amps

- 200 Amps

- High-Precision Plasma: 130 Amps / 260 Amps / 460 Amps (2x260 Amps)

- Marking capability option

- Multi-head oxy-fuel cutting capability

- Automatic oxy-fuel ignition

- Automatic torch height control

- Preview of upcoming program lines to detect sharp corners, maintaining high-speed cutting without slowing at entry/exit points of identical angles

- Resume-from-last-position function

- Compatible with standard DIN/ISO G-codes

- Supports DXF, ESSI, and NC toolpath files

- Ability to change all program parameters during operation

- Free AJANCAD Drawing Software

- Easy keyboard-based switching between plasma and oxy-fuel cutting modes

- Cutting speed up to 15 meters/min

- Optional ventilation system

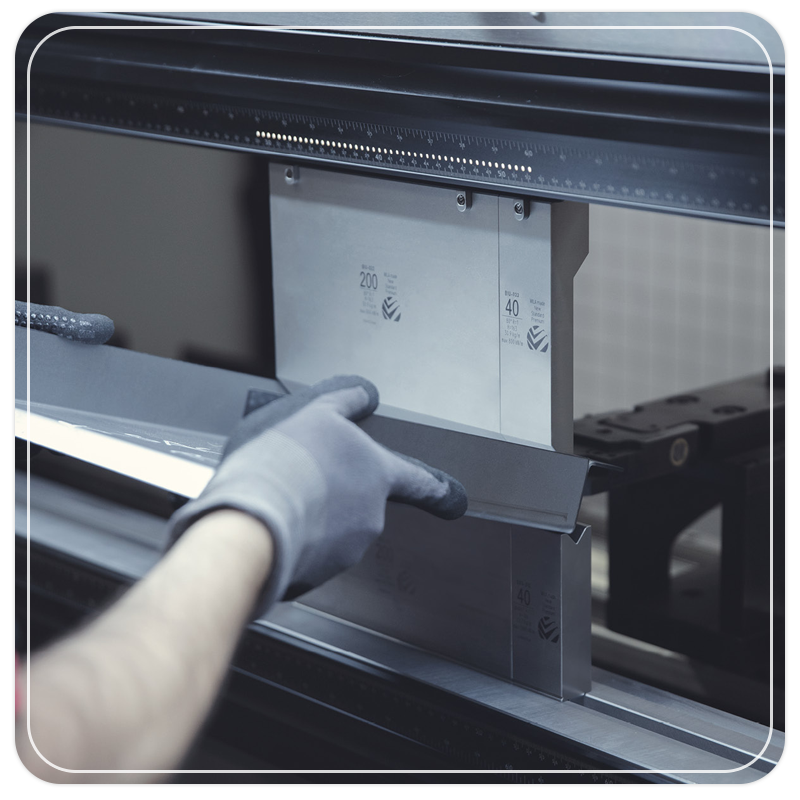

CNC Plasma + Oxy-Fuel Cutting (Baykal Machines)

Using our Baykal CNC Machines:

- PLASMA CUTTING up to 1–50 mm

- OXYGEN CUTTING up to 1–300 mm

CNC Baykal Plasma – Technical Specifications

- High-precision cutting and high-speed processing thanks to advanced plasma power supply

- Mechanical precision: ±0.1 mm

- Axis positioning speed: 30 m/min

- X and Y axes operate on precision linear rails

- Torch mechanism and height control operate via ball screws on dual linear guides

- Fast and precise positioning with AC servo motors

- Y-axis: dual synchronized servo drive

- X-axis: single servo drive

- Cutting table is mounted independently of the bridge and main body to maintain positioning accuracy under all loads

- Patented torch collision protection system

- Automatic torch height control

- Automatic fume extraction system with segmented lower section

- Windows-based CNC unit

- Automatic nesting software package

- Remote control option for long tables

- Optional dust and smoke collector unit with filters

- Supports both plasma cutting, oxygen cutting, or combined cutting operations